ASSIGNMENT

Philips’ new premium garment steamer has a 3D board which required a different board cover construction than usual.

PROCESS

Competitor brands are strongly developing in the field of boards and material choices, and I felt that Philips needed to keep up to maintain the market leader position. I researched different textiles for their heat resistance, permeability and moisture absorption qualities. Through prototyping I also created different construction pattern options to fit the cover on the 3D board as smoothly as possible, keeping the usability for the consumer in mind, as well as the production process.

RESULT

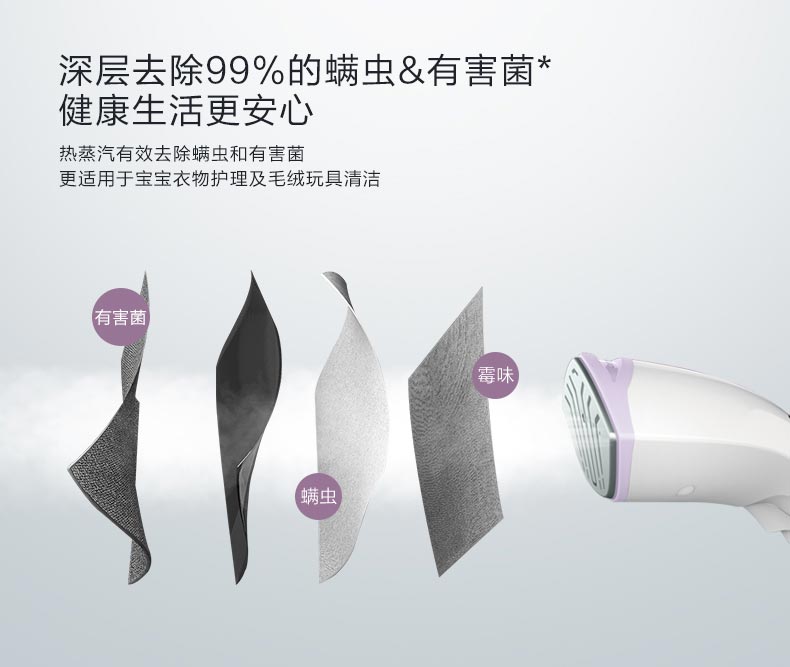

The unique combination of layered fabrics allows an optimal steam permeability and moisture absorption. The intuitive fastening process is extremely user friendly and makes the board cover fit like a glove. It’s unique in the market and it allowed Philips to add additional claims to the product.